Shrimp farming has become one of the fastest-growing sectors in aquaculture, but traditional methods often rely on high water exchange, costly feeds, and practices that strain the environment. Biofloc Technology offers a sustainable solution by turning waste into a valuable resource. This innovative system not only improves water quality but also provides shrimp with a natural protein-rich food source, reducing production costs and minimizing environmental impact. As global demand for shrimp rises, adopting Biofloc Technology ensures that farmers can achieve profitability while supporting long-term ecological balance.

As the global population grows, food production industries — including aquaculture — face the challenge of producing enough food without harming the planet. Shrimp farming, one of the most profitable aquaculture sectors, has expanded rapidly but often at the cost of high water usage, waste production, and dependence on expensive feed inputs.

Biofloc Technology (BFT) offers a sustainable alternative, improving shrimp health, reducing environmental impact, and cutting production costs.

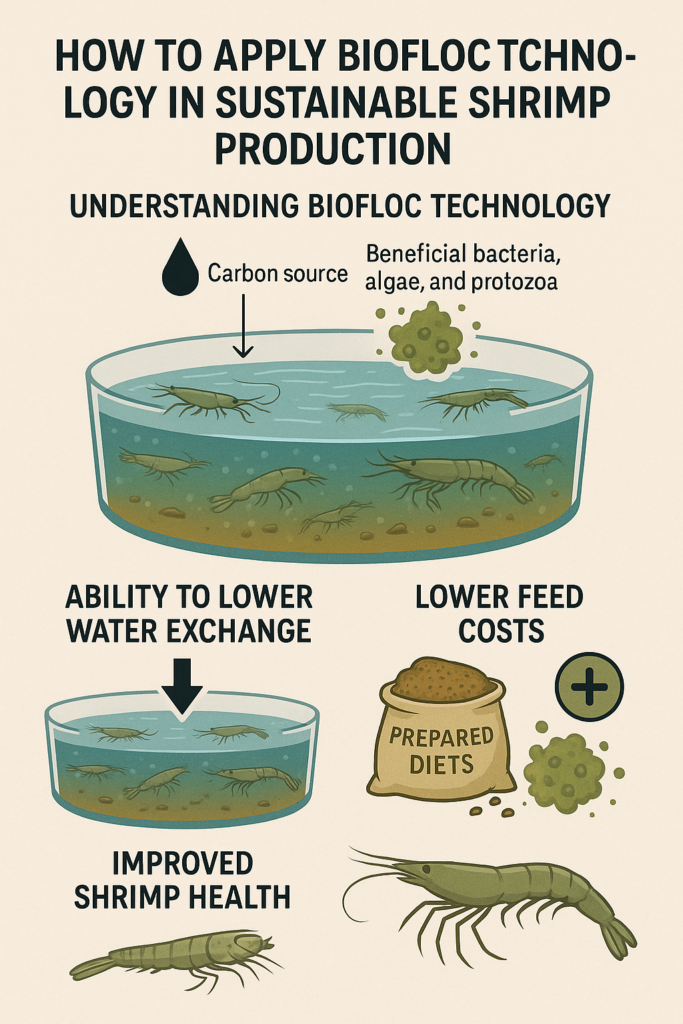

Understanding Biofloc Technology

Biofloc Technology is an innovative recirculating aquaculture system that creates a controlled microbial ecosystem in shrimp ponds. By adding carbon sources such as molasses or starch, farmers maintain a balanced carbon-to-nitrogen ratio. This balance stimulates the growth of beneficial bacteria, algae, and protozoa, which clump into bioflocs.

These bioflocs recycle waste, improve water quality, and serve as a high-protein, natural feed for shrimp — reducing reliance on commercial diets.

Benefits of Biofloc Technology in Shrimp Aquaculture

1. Reduced Water Exchange

Traditional shrimp ponds require constant water exchange, which can discharge nutrient-rich waste into nearby ecosystems. Biofloc systems recycle nutrients internally, minimizing waste discharge and conserving water. This makes BFT especially valuable in regions with limited freshwater or strict environmental regulations.

2. Lower Feed Costs

Since bioflocs contain proteins, lipids, and essential micronutrients, they act as a natural feed supplement. This reduces the need for expensive formulated diets and makes shrimp production more economical.

3. Improved Shrimp Health

Bioflocs compete with harmful bacteria, lowering the risk of disease outbreaks. They also strengthen the shrimp’s immune system, resulting in higher survival rates, faster growth, and improved production efficiency.

Challenges and Best Practices for BFT

Despite its many advantages, managing biofloc systems requires technical know-how. Farmers must:

- Maintain the right carbon-to-nitrogen ratio.

- Monitor key water parameters (pH, dissolved oxygen, ammonia).

- Ensure strong aeration systems for proper circulation.

- Receive proper training to avoid system failures that could cause production losses.

With good management, BFT can become a game-changer in shrimp aquaculture.

Conclusion: The Future of Sustainable Shrimp Farming

Biofloc Technology represents a transformative step toward sustainable, cost-effective, and environmentally friendly shrimp farming. By recycling waste into valuable biomass, conserving water, and reducing dependence on costly feeds, BFT aligns with global goals for sustainable food production.

With proper training and support, shrimp farmers can use biofloc systems to meet growing demand while protecting the environment.

Get more insight on biofloc technology and sustainable aquaculture at EAT Community

Biofloc Technology Related Articles & References

- Biofloc Shrimp Farming: Cultivation and Principles of Growing Shrimp

- Avnimelech, Y. (2012). Biofloc Technology: A Practical Guidebook. The World Aquaculture Society.

- Crab, R., Defoirdt, T., Bossier, P., & Verstraete, W. (2012). Biofloc technology in aquaculture: Beneficial effects and future challenges. Aquaculture, 356–357, 351–356. https://doi.org/10.1016/j.aquaculture.2012.04.046

- Emerenciano, M., Gaxiola, G., & Cuzon, G. (2013). Biofloc Technology (BFT): A Review for Aquaculture Application and Animal Food Industry. Biomass Now – Cultivation and Utilization, IntechOpen. https://doi.org/10.5772/53902

- Hargreaves, J. A. (2013). Biofloc Production Systems for Aquaculture. Southern Regional Aquaculture Center Publication No. 4503. https://srac.tamu.edu/

- Kuhn, D. D., Boardman, G. D., Craig, S. R., Flick, G. J., & McLean, E. (2009). Use of microbial floc generated from tilapia effluent as a nutritional supplement for shrimp, Litopenaeus vannamei. Journal of the World Aquaculture Society, 40(4), 573–582. https://doi.org/10.1111/j.1749-7345.2009.00274.x

- Martínez-Córdova, L. R., Emerenciano, M., Miranda-Baeza, A., & Martínez-Porchas, M. (2015). Microbial-based systems for aquaculture of fish and shrimp: An updated review. Reviews in Aquaculture, 7(2), 131–148. https://doi.org/10.1111/raq.12058

- The World Aquaculture Society (WAS). (2020). Advances in Biofloc Technology for Sustainable Aquaculture. https://www.was.org/

- FAO (Food and Agriculture Organization of the United Nations). (2020). The State of World Fisheries and Aquaculture 2020. Sustainability in Action. http://www.fao.org/fishery